Material Handling Solutions

Efficient material handling is critical to productivity, safety, and consistency across manufacturing and processing environments. Innovative Machine Corporation designs and builds custom material handling systems focused on the controlled movement, staging, and transfer of materials throughout a facility—independent of the web converting process.

IMC material handling solutions support batch and discrete material flow, including pallets, containers, rolls, parts, and assemblies. Systems are engineered to reduce manual handling, improve ergonomics, and maintain predictable throughput in heavy-duty and high-cycle applications. Our experience with large, heavy, and precision components allows us to design handling equipment that is both robust and reliable.

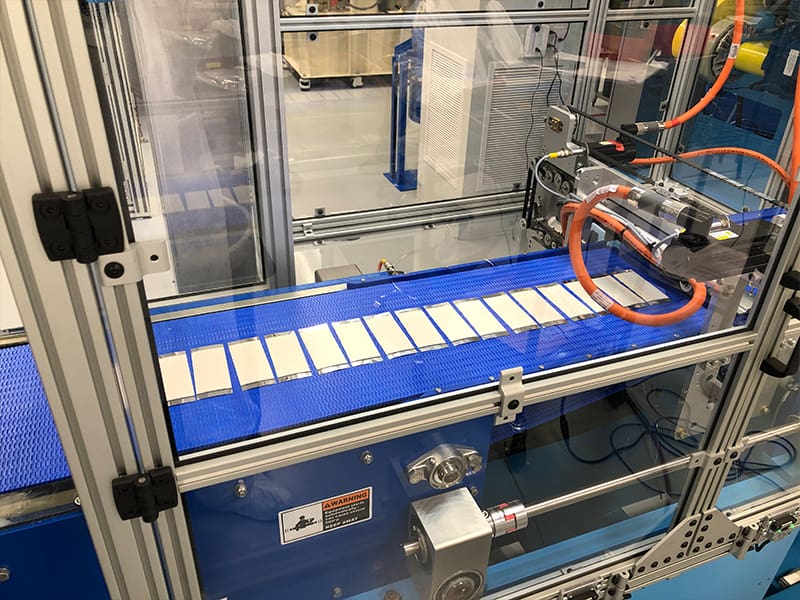

Material handling capabilities include pallet and chain conveyor systems, powered and gravity roller conveyors, lift tables, turntables, accumulation zones, transfer stations, and automated loading or unloading solutions. Systems may be manually assisted, semi-automated, or fully automated depending on process requirements and operational goals.

IMC approaches material handling as a complete system, considering plant layout, safety, workflow, and future expansion from the outset. Solutions can stand alone as independent handling systems or integrate with upstream and downstream manufacturing operations where required. Each system is custom-engineered to match the customer’s facility, material characteristics, production rates, and long-term operational needs.

- Advanced Controls & Operator Interface

- Automated Stackers

- Conveyers

- Pick & Place Systems

- Accumulators

- Stenters (Tenter)

- Lift Tables