Advanced QC Inspection Systems

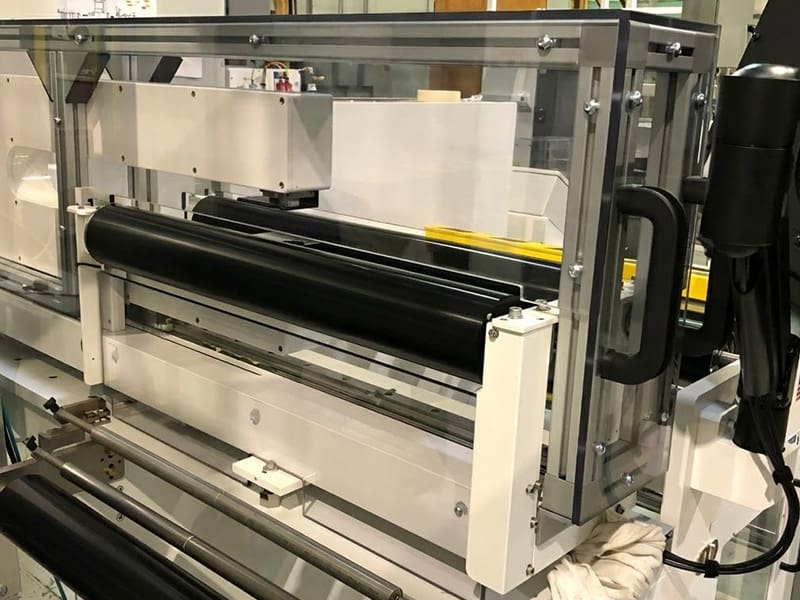

Quality assurance cannot wait for post-process lab checks. Modern web converting operations require real-time inspection and metrology to verify critical product attributes as material is being processed. Innovative Machine Corporation designs and integrates inline inspection and quality control systems that deliver high-speed, high-resolution analysis without interrupting production.

IMC inspection solutions combine precision mechanical design with advanced vision, sensing, and data-analysis technologies. We routinely integrate proven third-party metrology, vision, and gauging platforms—including web scanning cameras, optical measurement systems, thickness gauges, and specialized sensors—selected to meet the specific resolution, accuracy, and speed requirements of each application. These systems identify, track, and classify defects down to the micron level at full production speeds.

Real-time inspection data provides immediate process feedback, enabling operators and control systems to react quickly to quality deviations. Integrated data logging and traceability support statistical process control (SPC), quality reporting, and compliance with the stringent requirements of industries such as battery materials, films and foils, medical substrates, and advanced composites.

IMC engineers design inspection and metrology stations for seamless integration into coating, laminating, slitting, winding, and other converting lines. Whether incorporating a single inspection point or multiple synchronized measurement systems, each solution is engineered to ensure proper web stability, illumination, measurement accuracy, and long-term reliability within the production environment.

- Advanced Camera Systems from Multiple Vendors

- Laser or Ultrasonic Gauges for Thickness

- Beta or X-Ray Gauges for Density

- Integrated Marking Systems

- Advanced Control with Close Loop Capability

- Integrated with Customer QC System

- Back-lit Visual Inspection

- Roll Mapping & Defect Tracking